Capabilities & Services

Yankee Casting proudly serves our customers with state-of-the-art processes and services and has proudly advanced in the foundry of the future, by moving into Industry 4.0 where our processes and machines can adapt in real time.

This transformation is visible from our expanded foundry floor and throughout all of our processes which reduce waste, and improve results verifiably.

Capabilities

- Engineering

- CAD Modeling

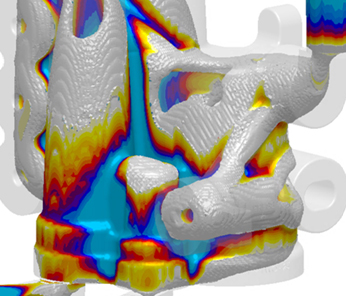

- Solidification Simulation

- In house Pattern Capabilities

- Available 3D mold printing

- Foundry

- Manufacturing Execution System

- In-process inspections

- Complex Core Assemblies

Pouring maximums:- Aluminum 1200 lb

- Magnesium 900 lb

- Metallurgical Lab

Chemical analysis Yankee Casting has the in-house capability to test all alloys poured. We use a Thermo Scientific Optical Emission Spectrometry (OES) to assure the chemistries meet the customer and/or internal requirements.- Mechanical properties testing - Tinius Olsen Tensile Tester to perform production and pre-production destructive tests

- Metallography evaluation

- NDT

- Fluorescent Penetrant Inspection (FPI)

- Digital Radiographic (X-Ray) Testing

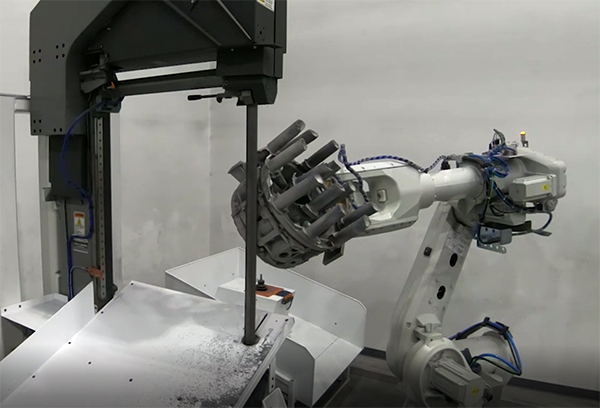

- Robotics

Yankee Casting uses ABB Robots for Robotic Bandsaw & Milling for gate removal to maintain consistency and accuracy, and to eliminate rework and reduce total processing time. - Welding

Yankee Casting is a Nadcap accredited welding facility with multiple personnel qualified to AWS and customer-specific standards proficient in welding cast aluminum and magnesium alloys. - Heat Treating

Yankee Casting is a Nadcap accredited heat-treating facility with in-house capabilities of solution and precipitation heat-treating from 250°F to 1010°F with hot water quench. - Inspection and Qualification

- Borescope Inspection

- Spot Facing / Targeting

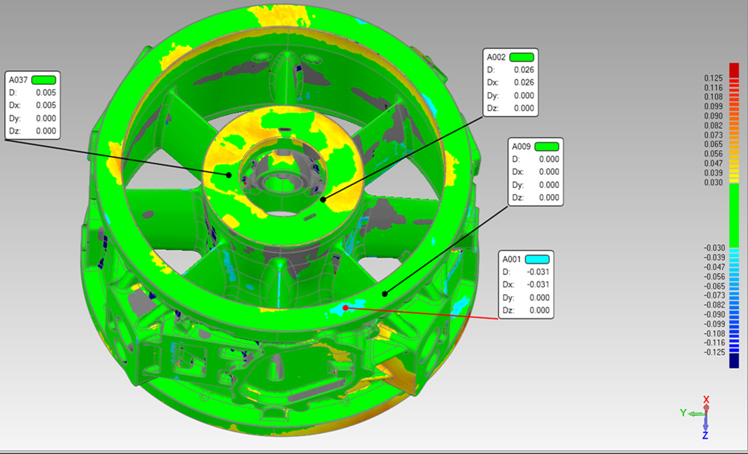

- Laser Scanning

- Ultrasonic Measurement Inspection